Our History

Toppan’s Journey

Limited Partnership

1900〜1909

At the start of the 20th Century, during the Meiji Period, Japan embarked on the path of modernization.

As Japan industrialized, many new companies meeting the needs of the population emerged one after the other with new technologies. Toppan's founders saw opportunities in fields such as the printing of securities and packaging based on the Erhöht letterpress method, state-of-the-art technology at that time.

1900

Toppan Printing Limited Partnership founded

More Infomation1908

Reorganized as Toppan Printing CO., LTD.

More InfomationThe era of our founding

In the 1880s, Edoardo Chiossone, a foreign technical advisor at the Ministry of Finance’s Printing Bureau (now the National Printing Bureau), trained many new engineers and contributed greatly to advances in Japan's banknote printing technology, including fine-line engraver operation, the Erhöht letterpress method, and watermark printing plate production.

Two engineers, Enkichi Kimura and Ginjiro Furuya, who learned the latest printing technologies under Chiossone and later founded Toppan Printing, thought of ways to further develop Japan's printing industry based on the most advanced printing technology at that time, the Erhöht letterpress. However, entering that business proved a very difficult endeavor as demand was weak for securities and other high-end printed items for which orders were expected due to an economic recession.

(first president)

At that time, Japan's tobacco industry was experiencing fierce competition between two private manufacturers, Murai Keitei and Iwaya Shokai. Kimura and Furuya, sensing a business opportunity, went to Iwaya Shokai with a proposal for outer box printing using the Erhöht letterpress method when they heard that Iwaya’s rival Murai Keitei was bringing in the latest American-made printing presses.

Feeling threatened by the expansion and bolstering of Murai Keitei’s facilities, Iwaya Shokai saw the appeal of products made with the elaborate Erhöht letterpress method. This is how Kimura and Furuya finally acquired regular orders using the Erhöht letterpress method, eight years after they had left the Printing Bureau.

Then, five founders, Kimura, Furuya, and three other investors, Kishi Ito, Tatsutaro Kawai (the first president) and Shinjiro Miwa, established Toppan Printing Limited Partnership at 1 Nicho-machi, Shitaya Ward, Tokyo (now 1 Taito, Taito Ward, Tokyo).

(Middle)Charter for the establishment of Toppan Printing as a company

(Right)Agreement for the establishment of the company

The year prior to Toppan Printing's founding, 1899, Enkichi Kimura drew up a charter for the establishment of a copper letterpress and lithographic printing house. Based on this, the five founders held discussions and drafted a charter for the establishment of Toppan Printing as a company. After negotiating several matters, they drafted an agreement for the establishment of the company.

These documents, which articulate the passion espoused by the founders in their intent to launch a venture company, are valuable documents that pass on the spirit of Toppan's founding to the present day.

Reorganization as Toppan Printing Co., Ltd.

In 1908, Toppan Printing Limited Partnership doubled its capitalization to 400,000 yen, reorganized and restarted as Toppan Printing Co., Ltd. What differed from the articles of incorporation of the original limited partnership company was the addition of "binding and sale of movable type casts" to prepress and printing by copper letterpress, copper steel engraving, lithograph, aluminum plate and applied photography plate. This reflects the fact that the company was targeting the field of letterpress printing in step with the increasing standard of living of the Japanese people, the advancement of culture, and the rapid advance of publishers.

postards at the head office plant

(around 1919)

1910 to 1919

The 1910s saw large numbers of people moving to urban centers with the development of industry resulting in the blossoming of consumer culture.

Beautifully designed department store posters, labor union posters and leaflets could be seen everywhere in towns, and printed matter grew in importance as a means for conveying various information. Toppan introduced offset printing and other new technologies from the United States and produced many types of printed matter to meet new demand.

1917

Acquired Offset Printing Limited Partnership

More InfomationAdvent and introduction of offset printing presses

In 1908, Max Schmidt, president of the Schmidt Lithograph Company in San Francisco, introduced the offset printing press to Japan. This development increased the momentum of offset printing research led by the Ministry of Finance’s Printing Bureau.

In 1911, Gennojo Inoue, the manager of Toppan who saw the future potential of the new technology before others, drafted a detailed plan proposing the introduction of offset printing presses to Toppan executives. However, as the company was experiencing financial difficulties at the time, the president, Tatsutaro Kawai, and other executives did not approve it.

Refusing to give up, Inoue assembled others in the company who understood offset printing and established a limited partnership called Offset Printing in 1913 equipped with the cutting-edge offset printing press. The products made by that company had superior workmanship and the astounding speed of cutting-edge offset printing enhanced its reputation, contributing to the steady growth of the company.

Before long, a great number of people at Toppan began leaning towards a merger with Offset Printing and, in 1917, an extraordinary meeting of shareholders resolved to acquire that company.

(1922)

1920 to 1929

In 1923, the Japanese economy was seriously impacted by the Great Kanto Earthquake. Subsequent reconstruction works greatly altered the Tokyo cityscape.

The wave of earthquake recovery efforts broadened the city limits, beautified the city and improved people's lives, spurring the development of urban popular culture that created demand for large-scale literary publishing and production. This era also witnessed the beginning of real demand for mass production and lower costs in the printing industry. which until then had mainly handled small lot production of various types of products.

1920

HB photo mechanical prepress method and equipment introduced from the United States

More Infomation1922

Completion of new plant at the head office

1926

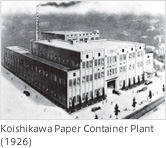

Opening of the Koishikawa Paper Container Plant in Nishi-Edogawamachi, Koishikawa Ward, Tokyo (now 1 Suido, Bunkyo Ward, Tokyo)

More Infomation1927

Establishment of the Osaka Branch Plant at 2 Ohito-Nishi, Nishi-Yodogawa Ward, Osaka (now 1 Oyodo-Kita, Kita Ward, Osaka)

Introduction of the HB photo mechanical prepress method

During the 1920s in the U.S., a precise and efficient platemaking method called the HB process began to be widely used in the industry for multi-color printing based on photo-applied planography technology and the step-repeat printing down method.

Koshiro Ichida of Ichida Offset Printing Co., Ltd. continued to negotiate with the HB patent holder in the U.S. in an effort to purchase the patent rights. Realizing the difficulty of such a purchase by a single company, Ichida pitched his idea to his friend, Toppan manager Gennojo Inoue. Inoue assembled six companies in the printing industry, including Toppan and Ichida Offset Printing, and established Japan H.B. Patent Platemaking Co., Ltd. This led to the first installation of HB process equipment at Ichida Offset Printing and then the second at Toppan the following year.

Absorption-type merger of Tokyo Shiki Co., Ltd.

On February 1, 1926, an extraordinary general meeting of Toppan shareholders was held where the merger agreement concluded with long-time close business partner Tokyo Shiki Co., Ltd. was approved. On April 8 that year, another extraordinary meeting was held to report the merger. As a result of this merger, all the facilities and personnel of Tokyo Shiki were taken over by Toppan and their Nishi-Edogawamachi Plant became our Koishikawa Paper Container Plant. This was Toppan's first step towards building the production system of its paper container and packaging section.

in its first phase of construction

1930 to 1939

The global financial crash pushed Japan's industrial sector into a deep depression that also left the printing industry in dire straits.

In such circumstances, Toppan's president at the time, Gennojo Inoue, considered Japan's future and the growth potential of the printing sector and decided to embark on the construction of one of the world's most modern plants.

1938

The Itabashi Plant is completed and starts operations in Shimura, Itabashi Ward, Tokyo (now 1 Shimura, Itabashi Ward, Tokyo).

More InfomationConstruction of the Itabashi Plant

The global financial crash originating in the New York stock market led the Japanese industrial sector into a serious depression.

However, Toppan survived this tough period with cost reductions and aggressive sales that resulted in the gradual expansion of our business. As the economy slowly recovered, printing houses that had collaborated to overcome the harsh conditions of the depression gradually came to compete with one another. As this was occurring, President Inoue conducted a survey of Japan's paper consumption in an effort to gauge the future potential of its printing industry. Results showed that paper consumption was much lower in Japan than in major developed countries, and that the production volume of printed matter was also low. He saw that Japan's printing industry was still developing and predicted a future expansion in demand.

Based on the assumption of an explosion in future printing demand, Toppan decided to build a new plant with a scale of facilities that could rival any other company and immediately began making plans for construction.

The new Itabashi Plant was designed with a total area of roughly 66,000 square meters. The plant building itself had 40,000 square meters and, with its Western-style garden and exercise facilities, was a modern facility that renewed the image of plants of that era.

patriot group at work

1940 to 1949

Under wartime regulation during World War II, the entire industrial sector of Japan was under general mobilization for the war effort.

Companies were to participate in the general mobilization, and the printing industry was no exception. There were government bonds and other securities certificates to be issued along with other mounting government demands which led to printing houses being very busy. After the end of the war, the need for economic controls in the ensuing period of confusion meant that demand from the government continued for some time.

1945

Toppan’s bid to the Ministry of Finance to print new designs for all Bank of Japan notes was accepted (¥1,000, ¥500, ¥100, ¥10, ¥5, ¥1)

More Infomation1946

Itabashi, Fuji, and Osaka Plants designated as Ministry of Finance administered plants under the regulations for management of currency manufacturing plants (effective until 1952)

Postwar rush

After the war ended, Toppan was busy meeting demand from the government, such as printing Bank of Japan notes, postage stamps, and lottery tickets.

In October 1945, the Ministry of Finance at that time announced the production and issuance of new Bank of Japan notes whose designs would also be done by experts at private printing houses. For the designs of new yen banknotes, 47 entries were submitted from the Printing Bureau as well as from Toppan and other major printers for consideration by the Ministry, which ultimately selected Toppan’s designs for all six bills, the ¥1,000, ¥500, ¥100, ¥10, ¥5 and ¥1.

For postage stamps, because the Ministry of Finance’s printing presses and other equipment for producing stamps were destroyed in an air raid, the Printing Bureau was making some postage stamps at a banknote printing plant and others were outsourced to private printing companies. At that time, glue-less, unperforated stamps were called “third issues of the Showa series” and much of the portion consigned to private printers went to Toppan. Also, as soon as regional lottery ticket issuance was permitted, nine prefectures immediately issued regional recovery lottery tickets. Toppan got orders for printing those of three prefectures for the first formal regional lottery, Fukui, Kanagawa and Niigata.

at the Itabashi Plant

1950 to 1959

In the mid-1950s, seeing the signs of the postwar recovery, Japan ushered in a high level of economic growth founded on technical innovation.

Despite the confusion spawned by the postwar recovery, a great multitude of people craved print culture. New books and magazines were published one after the other and a high-volume, low-cost production system was needed by the printing industry. In the midst of all this, Toppan's Itabashi Plant gradually implemented a system for mass production.

1951

Development of platemaking and printing technology for multicolor figure printing (MCF printing) for securities

More Infomation1958

Start of platemaking and printing of decorative paper for construction materials

Development of platemaking and printing technology for MCF printing

Toppan, which had focused much energy on the printing of securities since its founding, created new possibilities in that field with advances including the development of platemaking and printing technology for MCF printing for securities. For Sammel MCF printing, Toppan began using a four-color sheet-fed web press (MCF press). When printing with this method, the colors of pattern lines change midway through the process resulting in unique prints with absolutely no misalignments. That is why we call it MCF, short for “Multi Color Figure,” printing.

This press was widely used to meet demands for preventing counterfeit securities, and MCF printing became synonymous with relief printing.

1960 to 1969

Beginning of high-level economic growth and mass consumption in Japan

With high-level economic growth and a rapidly expanding private sector in Japan, wages rose and people began looking to live better, with trends including the purchasing of durable consumer goods. The era of mass consumption started in earnest when varied and diverse printed matter in the form of durable goods catalogs and supermarket fliers, etc. were distributed en masse. The product packaging industry and other sectors also faced demands for highly-appealing products for consumers.

1960

Experimental plant established for precision parts, such as masks for mesa transistors and shadow masks for television cathode-ray tubes.

Establishment of technology research facility at the Koishikawa Plant

More Infomation1961

Toppan Printing Service Center opened in Ginza, Tokyo (now the Toppan Idea Center).

More Infomation1963

Toppan Printing Co., (H.K.) Ltd. established in Hong Kong.

1964

Representative office opened in New York.

1965

Toppan Moore Business Forms Co., Ltd. (subsequently Toppan Forms Co., Ltd.) established as a joint venture with Canada's Moore Corp.

First domestic production of masks for mesa transistors

From the late 1950s, Toppan developed new technologies utilizing print platemaking technologies. These included masks for transistors and synchronized sheets using magnetic ink.

After successfully producing masks for mesa transistors domestically, Toppan used this opportunity to strengthen its mask making operations.

In 1960, when our technology research facility was launched, a team was assembled to research and commercialize transistor and shadow masks, and production began at the experimental plant. The same year, Toppan received a subsidy for industrial research and commercialization related to shadow evaporation masks for mesa transistors from the Ministry of International Trade and Industry (now the Ministry of the Economy, Trade and Industry).

Establishment of the Service Center (now the Toppan Idea Center)

In January of 1961, Toppan established its vanguard for new business development, the Toppan Printing Service Center, in Ginza, Chuo Ward, Tokyo. Here, a newly established design and planning department was permanently stationed, through which, in addition to existing business methods, we aimed to further promote efforts to secure business by taking orders for everything from printing manuscript drafting to design and layout.

Subsequently, the Service Center was renamed the Toppan Idea Center (TIC) in 1964 and, the following year, the Toppan Idea Center Osaka was established. Since then, TICs have been established in each major city in Japan.

to the Asaka Plant's clean room

1970 to 1979

The Dollar Shock and second Oil Shock disrupted the foundation of Japan’s high-level growth supported by a stable yen to U.S. dollar exchange rate and low-cost energy.

In 1974, Japan recorded negative growth for the first time since the end of World War Ⅱ. Faced with this crisis, the private sector in Japan took initial steps toward stable growth by downsizing management and streamlining operations. Toppan introduced computerized typesetting, accelerated overseas expansion, strengthened electronics products, and embarked on other ambitious initiatives to expand business.

1970

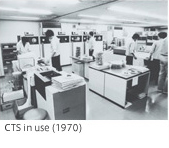

Computerized typesetting system put into practical use for the first time in Japan.

More Infomation1971

Toppan Printing Co. (America), Inc. established in New York.

Representative office opened in London.

More Infomation1972

Central Research Institute established as the core base for technical development.

1973

Numerous technologies exported overseas following completion of the revolutionary Toppan TH Gravure Process for prepress.

More Infomation1976

Toppan EP-PAK paper containers for long-term storage of juice, alcoholic beverages and other liquids developed.

More Infomation1978

Multiplex-type hologram developed with Tokyo Institute of Technology and Fuji Photo Optical Co., Ltd.

First practical implementation of computerized typesetting in Japan

In the late 1960s, with the advent of the information age, the sheer volume of information being printed increased more and more and the need to switch from manual typesetting to a more mechanical, rational system pervaded the industry. The Itabashi Division’s engineering department led Toppan’s efforts to examine the feasibility of computerized typesetting. Then, in 1968, we focused on creating a CTS (Computerized Typesetting System) based on photo-composition methods and carried out development of the new system in collaboration with Fujitsu Limited.

After CTS was fully implemented, the arrival in the 1970s of compact, affordable computers capable of processing huge amounts of information at high speed enabled the broader dissemination of CTS.

Proactive overseas market expansion

Along with the start of our Foreign Division in 1960, Toppan’s overseas sales activities were invigorated by an increase in Japan’s international competitiveness. At first, business from overseas was consigned for production at plants located in Tokyo. However, as orders from foreign countries increased, the need to meet delivery deadlines and control transportation costs for overseas exports, and for sales and production sites to be in line with local demand and technical levels, became pressing. This led Toppan to establish a joint venture with KMI Co., Ltd. of South Korea as well as open representative offices in Sydney and London, establish a subsidiary, Toppan Printing Co. (America), Inc., in New York, construct a new company building for our Hong Kong subsidiary, and undertake other initiatives to strengthen our overseas operations.

Completion of the Toppan TH Gravure Process

In October 1973, the development of the technology for the TH Gravure Process, which began in the mid-1960s, was completed. With conventional gravure printing, there were difficulties with the stability of color reproduction in terms of definition and gradation. However, Toppan succeeded in developing a revolutionary halftone gravure platemaking method.

This development quickly became well-known overseas, and in 1976 Toppan signed an exclusive technology licensing agreement for use in Switzerland with Conzett & Huber. A similar agreement was also concluded with American printing company R.R. Donnelley & Sons. The TH Gravure process was subsequently exported to Spain, Sweden, Australia, South Africa, Austria, and the U.K. in the 1970s.

Development of the EP-PAK―A multi-layer laminated paper-based container for liquids

In the late 1970s a variety of paper-based liquid containers suited to different purposes began to be seen. Three-layer laminated containers consisting of polyethylene and paper were used for milk and fruit juices, but Toppan improved upon these to develop the Toppan EP-PAK, a paper-based container for liquids, in 1976.

The Toppan EP-PAK is a multi-layer container. The layer that comes into contact with liquid is polyethylene. On top of this layer are aluminum foil, polyethylene, paper, and polyethylene, completing a five-layer structure. The special feature of the Toppan EP-PAK is that the cut surfaces of the paper are folded back so that they do not come into contact with the liquid inside, providing excellent prevention of permeation and enabling storage over long periods. The Toppan EP-PAK is therefore ideal for substances such as Japanese sake and soy sauce.

1980 to 1989

As an economic giant and a driver of the global economy, Japan was expected to lead international cooperation and economic recovery efforts.

Domestically, the legal framework for telecommunications was revised and expectations for new means of conveying information powered by computers heightened. This technological transformation provided momentum for electronics related businesses that had employed the sophisticated and precise technologies of printing since the 1960s.

1980

Toppan Video Prepress System, the first system in Japan to carry out direct platemaking from video signals, developed

More Infomation1983

IC Chip-in Card with integrated circuits developed jointly with Toppan Moore Business Forms Co., Ltd. and Tokyo Magnetic Printing Co., Ltd.

More Infomation1985

Franco-Japanese Modern Poster Exhibition held in Tokyo with France's Ministry of Culture

1986

New head office building and Toppan Technical Research Institute opened

More Infomation1987

Printing Archive opened

More Infomation1988

Computer graphics stereo (3D) printing technology developed

High-definition image data for color printing transmitted internationally, used at Seoul Olympics

More InfomationCommercialization of the Toppan Video Prepress System

Up until the 1970s, in order to use images from television as printing artwork, it was necessary to photograph the image on the television screen and use the resulting color photograph as the printing artwork. However, this method made it difficult to achieve satisfactory quality in terms of resolution, color tone, and gradation.

To overcome these issues, development of the Toppan Video Prepress System was completed in the spring of 1980. This was a system for producing the four plates (C, M, Y, Bk)* used for color printing from the image signal by inputting the VTR image signal directly into a color scanner. This was useful if only video from a video tape was available or in the case of live sports broadcasts and breaking news, and enabled the extraction of decisive moments from continuous video and the production of continuously decomposed photographs. The system was used for numerous magazines focusing on international sporting competitions and major events, and its reputation was further enhanced.

*C=Cyan; M=Magenta; Y=Yellow; Bk=Black

Development of IC Card

In October 1983 Toppan completed the development of the IC Card, a plastic card with an IC chip embedded in it. This card drastically expanded the scope of use for cards by having an IC chip embedded in a limited space without affecting the conventional functions of cash and credit cards.

The IC chip embedded in the card did not just increase the amount of information stored but also enabled it to be used as an intelligent card with a "brain" of its own. As more complex information processing became possible by connecting to a host computer via a terminal, IC cards enhanced confidentiality and enabled advanced processes to be performed with a single card.

Opening of Toppan Technical Research Institute and Printing Archive

In July 1986 the Toppan Technical Research Institute was opened in Sugito, Saitama Prefecture, as the core facility for Toppan's research activities. The Institute consists of an administration building, a testing building, and a research building. It consolidated research laboratories that had been independent of each other handling different products, enabling researchers from different disciplines to interact with and learn from each other. The essential concept was not to integrate research in each field but to stimulate human interaction by concentrating research resources at a single facility, and bring about the cross-fertilization of technology "seeds."

In 1987, the Printing Archive was opened inside the Technical Research Institute to promote general understanding of Toppan and the printing industry. This evolved into the Printing Museum, which was opened in 2000.

International transmission of image data at Seoul Olympics

Toppan had previously handled the remote transmission of high-definition data for printing, but in September 1988 it created a network for the transmission of high-definition color images from the Seoul Olympics. Toppan's image transmission and prepress technologies contributed significantly to the photographic coverage of the Olympics. Considerable advances were made in image compression and restoration techniques, and technology for taking NHK hi-vision broadcasts straight to prepress was used.

of LCD color filters

1990 to 1999

The effects that ensued after the bursting of the bubble economy were an enormous weight on the Japanese economy.

Meanwhile, the IT revolution brought various changes to business and people's lives. The printing industry was expected to assume a new role as “mainstay of the culture and information industry,” but there were also worries that our industry would shrink.

1991

Ecology Center opened

Collection and reprinting of Best 100 Posters of Japan completed

1993

Tokyo Metropolitan Government Prepress Toppan Co., Ltd. (now Tokyo Challenged Plus Toppan Co., Ltd.) established in collaboration with the Tokyo Metropolitan Government and Itabashi Ward as "third-sector" corporation employing persons with disabilities

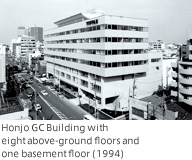

1994

Honjo GC Building completed, Toppan Prepress Center opened

Internet-based shopping mall experiment Cyber Publishing Japan launched

More Infomation1995

Collection and reprinting of Best 100 Posters from Europe & the United States completed

1996

Sales of Cartocan paper-based beverage container launched

Best 100 Posters from Europe & the United States wins the Mécénat International Award at the 1996 Mécénat Awards

More Infomation1997

Sakado Plant completed and opened

1998

Toppan Forms Co., Ltd. (now TOPPAN Edge Inc.) listed on the First Section of the TSE (Tokyo Stock Exchange)

1999

Bitway digital content distribution service launched

More InfomationLaunch of Cyber Publishing Japan experiment

In December 1994 Toppan launched an Internet-based information provision experiment in collaboration with Keio University and involving Kyodo News, Kirin Company, Limited, Shiseido Company, Limited, and Shogakukan Inc. This system involved creating a virtual shopping mall on the Internet, establishing store-like corners for each of the participating companies, and making it possible to view information provided by selecting a store. This was the first example of multiple companies working together in such a way.

Toppan provided the work stations and Internet environment for the experiment and established www servers in Tokyo and Los Angeles. Together with the participating companies, Toppan accumulated expertise in business, advertising, and network publishing using the Internet.

Launch of sales of paper-based Cartocan beverage container

The Cartocan, a paper-based beverage container that enables storage over long periods at room temperature, went on sale in 1996. The Cartocan has the same shape as a metal can but is almost entirely made of paper and can be sold via conventional vending machines. It has several advantages, including that it can be heated in a microwave oven and can be easily incinerated or recycled. Cartocans are produced using purpose-made forming and aseptic filling machines but the advantage is that there are not costs for the transportation of empty containers because all processes from forming from a roll to filling can be carried out on an integrated line.

The appearance of this revolutionary new product had a significant impact. It has enjoyed praise on many fronts, receiving an award for excellence at Nikkei Inc.'s Nikkei Superior Products and Services Awards, and in 1997 winning the 21st Kinoshita Prize at the Japan Packaging Institute's Packaging Contest.

Launch of Bitway

Toppan launched Bitway, a new business specializing in Internet-based distribution of information, in July 1999. In this business, Toppan does not directly sell information itself, but provides the information distribution network linking information providers and Internet service providers (ISP), and offers a system that enables the collection of fixed distribution fees every time information is sold to a user. Bitway has subsequently expanded operations by devising various projects as a core element of Toppan's Internet content business.

2000 to 2009

The structure of the world economy underwent a major transformation in the wake of the global financial crisis and the rise of the BRIC economies and other emerging markets.

Many developed countries including Japan, faced with an aging society coupled with a low birth rate and the diffusion of new media, witnessed the diversification of consumers and a shift in society's expectations toward the private sector. Under such conditions, Toppan saw the changing market as a great opportunity and continued to grow by creating new businesses and investing in the next generation.

2000

Toppan Koishikawa Building completed

Toppan Hall and the Printing Museum, Tokyo opened

Toppan Fair 2000 held in six locations in Japan

Applied research for digitally archiving cultural assets of the Forbidden City commenced in collaboration with China's Palace Museum

More Infomation2001

Toppan 100 Years―Business History of Toppan, 100 Prints from 100 Years, and artes imprimendi published

Shufoo! advertising flyer market launched

2002

Printed wiring board company NEC Toppan Circuit Solutions, Inc. established in cooperation with NEC Corporation

Mécénat Encouragement Award received at the 2002 Mécénat Awards ceremony for operation of Toppan Hall

2003

Contactless smart card SMARTICS-Fe developed

Shanghai Toppan Co., Ltd. and Shanghai Toppan Printing CO., LTD. established

Institute for Digitization of the Palace Museum Heritage opened within China's Palace Museum

More Infomation2004

Award for Distinction as a Corporate Citizen received from Bunkyo Ward in Tokyo

Production of world’s first sixth-generation-size color filters commenced

Shares of three printing-related Japan Tobacco, Inc. subsidiaries acquired

2005

Acquisition of DuPont Photomasks Inc. completed, Toppan Photomasks launched

Joint development agreement for state-of-the-art photomasks concluded with IBM of the U.S.

Industrial Materials Division merged with Toppan Cosmo to establish a new Toppan Cosmo, Inc.

Fully-automated SNP analysis system integrating test reagent and chip developed with RIKEN and Shimadzu Corporation

More Infomation2006

TOPPAN SOLUTION WORLD 2006 exhibitions held in seven locations across Japan

Contract concluded with the government of Greece to provide a secure document issuance system

Local subsidiary, Toppan Printing Greece S.A., established

Cartocan paper-based beverage container presented with the Minister of Agriculture, Fisheries and Forestry Award at the third Eco-Products Awards

More Infomation2007

Toppan named one of the Global 100 Most Sustainable Corporations in the World (first of three consecutive years with 2008 and 2009)

Nanotext, a new technology for incorporating minute characters into holograms, developed

VR content The Palace VR―The Forbidden City: The Place of Emperors made available for public display

More Infomation2008

Toppan Charity Concerts held to support education aimed at improving literacy

Agreement with DuPont of the U.S. for solar cell backsheets concluded

Major Singapore printer SNP Corporation acquired

2009

Fukaya Plant opened as a manufacturing base for next-generation functional films

Gold medal in printing category at WorldSkills competition

New plant in Beijing, China, constructed for book, magazine and package printing

More Infomation100th Anniversary of Founding―A Second Beginning

Toppan celebrated 100 years of business in 2000 and undertook a range of activities to mark the occasion. As part of this, 2000 was positioned as a "second beginning" for the company―a year for consolidating the achievements of the past 100 years and creating a new vision for the company moving into the 21st century. Activities focused on transforming the company to establish the mindset and culture to achieve further, sustainable growth.

The Toppan Koishikawa Building was opened in April 2000 on land redeveloped in the Koishikawa area Tokyo as a core base for advances in the field of information communication. In June, the Toppan Hall classical music venue was opened as part of efforts to contribute to society and culture. Then, in October, the Printing Museum, Tokyo was opened to present the past, present, and future of the relationship between printing, society, and culture. The final undertakings marking the anniversary were the publication in June 2001 of Toppan 100 Years―Business History of Toppan and 100 Prints from 100 Years, records of the company's activities over the previous century, and artes imprimendi, detailing numerous events related to printing and communication.

Opening of Palace Museum Digital Institute

Toppan and China's Palace Museum launched a joint project focused on using digital technologies for the preservation and display of the cultural heritage of the Palace Museum in 2000. In October 2003, the Institute for Digitization of the Palace Museum Heritage (Palace Museum Digital Institute) was opened inside the Palace Museum.

One of the outcomes of joint research was the production of a piece of VR content entitled The Palace VR―The Forbidden City: The Palace of Emperors Part 1―Hall of Supreme Harmony in 2003. The second part of the production, entitled The Three Great Halls was completed in 2005. This content reconstructs the Forbidden City of the era spanning from the reign of the Kangxi Emperor to that of the Qianlong Emperor (circa 1660-1790). In October 2006, the first ever three-dimensional measurement of cultural assets at the Palace Museum was conducted in the Hall of Mental Cultivation, one of the Forbidden City's most famous halls.

Launch of Toppan Photomasks and signing of joint development agreement with IBM

In April 2005 leading U.S. semiconductor photomask and electronic design software developer and manufacturer DuPont Photomasks became a wholly-owned subsidiary and was integrated into the Toppan Group, the new business launching as Toppan Photomasks. This enabled Toppan to become the only photomask supplier in the world with production locations in North America, Europe, and the Asia-Pacific region, and to secure a leading share of the global market.

Toppan also signed a joint development agreement with IBM Corporation in May of the same year, focusing on photomasks for the 45 nm process (1 nanometer=1 billionth of a meter) for next generation semiconductor manufacture. This enabled a framework to be put in place that could handle optimal photomask development and the manufacture of cutting-edge photomasks essential for information communication devices and digital appliances as the market for them grows and they become more advanced with multiple functions.

Agreement with Greek government to supply secure document issuance system

Toppan entered into a 10-year (April 2006-April 2015) supply agreement with the Greek government for a secure document issuance system. This was a newly-developed system from Toppan and its special feature is the ability to issue a range of secure documents, including passports, ID cards, and driving licenses. In August 2006 this system began to be used for issuing Greek IC passports and e-ID cards for the Hellenic Police. Up to that point, technology developed by Toppan had been adopted by 12 countries and used for the issuance of approximately 100,000 accreditation cards (AD cards) for athletes and staff at the Athens Olympics in 2004.

Selection as one of the Global 100 Most Sustainable Corporations in the World

Toppan became the first company in the Japanese printing industry to be selected as one of the Global 100 Most Sustainable Corporations in the World when it was announced during the annual meeting of the World Economic Forum in Davos, Switzerland, in January 2007. The Global 100 is a selection of 100 companies from around 1,500 surveyed that are rated as having the highest levels of competence in managing social, environmental, and governance risk and business opportunities, and demonstrating excellent sustainability.

Toppan was subsequently the only Japanese printing industry company to be selected for three consecutive years, from 2007 to 2009.

Gold medal in the printing category at WorldSkills

Noriaki Kikuchi, an employee of Toppan Group company Toppan Communication Products' Sapporo Plant, represented Japan and won Japan's first ever gold medal in the printing category at the WorldSkills competition held in Calgary, Canada, in September 2009. Mr. Kikuchi was the second Toppan employee in a row to represent Japan, following on from the 2007 competition held in Numazu, Shizuoka, Japan, when printing first became an official category.

Mr. Kikuchi's gold medal was the result of Toppan's efforts to pass on skills from generation to generation and a testament to the high level of technical competence in the Japanese printing industry.

2010 to 2019

With the Japanese economy yet to see a significant turnaround, consumers began to put greater emphasis on new forms of added value. In addition to demand for higher quality, this meant a stronger focus on the digital revolution and consideration for the environment.

Businesses needed to respond flexibly to changing values in an era defined by the progress of digitalization and globalization. Incorporating the Sustainable Development Goals into its perspective, Toppan continued to focus on creating new growth engines and generating new value for society by leveraging its core printing technologies to transform business models.

2010

Ceremony for establishment of monument honoring predecessors to mark Toppan's 100th anniversary held at Mount Koya, Japan

Comprehensive service supporting carbon offset for corporate advertising tools launched

Award for printing culture promotion received at the 2010 Mécénat Awards ceremony for operation of Printing Museum

2011

Cloud-based e-book store BookLive! launched targeting the expanding e-book market

Large-scale orthoscanner developed for digitally archiving cultural assets

Mobile library Book Wagon launched for areas affected by Tohoku earthquake and tsunami

2012

Radioactive material absorbing zeolite functional paper developed

Digital signage-based next-generation indoor guidance system launched

PRIME BARRIER Retort Grade developed with the world's highest level post-sterilization oxygen gas barrier performance for a transparent barrier film

2013

TNM & TOPPAN Museum Theater established with Tokyo National Museum inside the Museum's Toyokan (Asian Gallery)

Singapore Branch established to advance transformation of the business model on a global scale

High-security Toppan Group Data Center consolidating core systems completed

High-performance copper touch panel module developed and world's first mass production of such a module commenced

2014

Toppan recognized in Japanese Ministry of Economy, Trade and Industry's Diversity Management Selection 100

Gunma Central Plant opened as core plant for global flexible packaging production

Sales of Toppan Bunkyutai™ font products launched by Morisawa Inc.

More Infomation2015

New free-of-charge learning service Manabi Get! launched

GPS-linked content distribution platform Street Museum launched

2016

Toppan Hall receives 47th (2015) Suntory Music Award

Toppan USA's Georgia Plant opened as Toppan's first overseas transparent barrier film production base

Sales of liquid crystal light control film LC MAGIC launched

Toppan becomes official partner of Tokyo 2020 Olympic and Paralympic Games

More Infomation2017

Toppan recognized as White 500 outstanding company under the Japanese Ministry of Economy, Trade and Industry's Certified Health and Productivity Management Organization Recognition Program

L・IF・E showroom opened to present fulfilling lifestyles of the future in the fields of packaging, décor materials, and industrial materials

2018

Toppan included for the first time in the Health & Productivity Stock Selection chosen by Japan's Ministry of Economy, Trade and Industry and the Tokyo Stock Exchange

Toppan's innovative initiatives recognized with inclusion for the first time in the list of Competitive IT Strategy Companies published by Japan's Ministry of Economy, Trade and Industry and the Tokyo Stock Exchange

NIPPON GALLERY TABIDO MARUNOUCHI opened as a co-creation space supporting efforts to revitalize regions of Japan and establish the country as a major tourist destination

More Infomation2019

NAVINECT™ launched as Toppan's solution for supporting digital transformation of manufacturing

Leading global décor printer Interprint joins the Toppan Group

Toppan develops PET, PP, and PE monomaterials for functional packaging

TOPPAN SDGs STATEMENT published

More InfomationGunma Central Plant

Georgia Plant

Entrance to NIPPON GALLERY TABIDO MARUNOUCHI

Design Center at Interprint's headquarters in Arnsberg, Germany

2020 to 2023

2020

Invested in U.S.-based b8ta,Inc. and started collaboration in the next-generation retail business, RaaS (Retail as a Service).

Established a new DX support BPO company, TB Next Communications Co., Ltd., with BELLSYSTEM24.

Established a new joint venture with Kodansha Ltd. and cyber communications inc. to promote DX in the content business.

Succeeded in joint development and social implementation of “Face Shields for Eating and Drinking” based on results of research performed using the Fugaku supercomputer.

2021

PASS-CODE infectious disease information management app developed

Metapa virtual mall app developed

U.S. packaging supplier InterFlex Group acquired

Indian film manufacturer made a consolidated subsidiary

2022

Smartphone app that can decipher historical cursive documents with AI-OCR developed

MiraVerse™ metaverse platform for business developed

AVATECT platform for verifying the authenticity of avatars developed

Toppan Photomask Co., Ltd. launched (April 2022)

2023

Establishment of transparent barrier film production site in the Czech Republic announced

TOPPAN Edge Inc. launched

Toppan Forms Co., Ltd. merged with Toppan Inc.’s Security Subdivision to make a new start as TOPPAN Edge Inc. on April 1, 2023

TOPPAN Holdings Inc. established as a holding company

To achieve integrated management of Toppan’s operating companies from the perspective of Groupwide optimization, TOPPAN Edge Inc., TOPPAN Inc., and TOPPAN Digital Inc. were founded under the holding company. TOPPAN Inc. is centered on the main divisions of the former Toppan Inc. while TOPPAN Digital Inc. drives the digital transformation business across the Toppan Group

Establishment of TOPPAN Holdings Inc.

Toppan transitioned to a holding company structure in October 2023. In order to adapt to the rapidly changing business environment and transform the business portfolio, it was deemed necessary for the Toppan Group to make even more concerted efforts to maximize synergy and, through strengthened Group governance, evolve into a management structure that enables optimal allocation of management resources and prompt decision-making.