© TOPPAN INC. © TOPPAN Edge Inc.

Tokyo – May 10, 2024 – TOPPAN Inc. (TOPPAN) and TOPPAN Edge (TOPPAN Edge), TOPPAN Group companies and wholly owned subsidiaries of TOPPAN Holdings Inc. (TYO: 7911), have enhanced e-Platch™, the smart inspection support service offered by the TOPPAN Group, by adding a new solution in the form of a sensor that enables remote detection of water, chemical, and oil leakage at factories and other facilities. Demonstrations will begin in June this year with mass production and sales launch targeted for September.

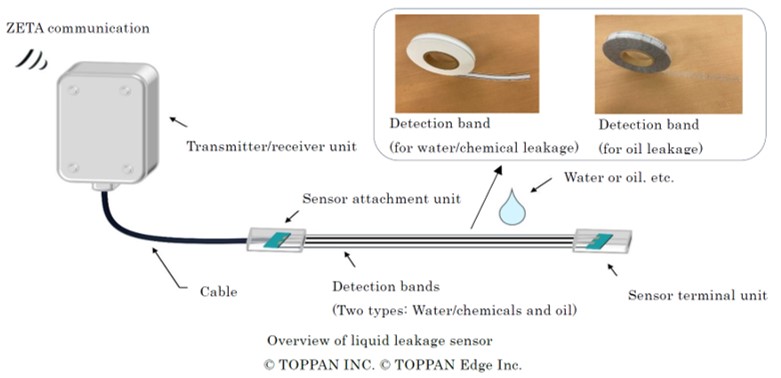

A feature of the new liquid leakage sensor is the detection band in tape form that applies technology used for printed wiring. Two types of detection band are used: one for detecting water and chemicals, the other for detecting oil. The new sensor will be provided as an addition to the e-Platch™ smart inspection support service to enable a wider range of liquid leakage detection.

e-Platch™ will also become easier than ever to adopt due to the planned introduction of a new pricing plan with reduced initial costs, something that has been eagerly anticipated since the e-Platch™ service was launched, as well as an external API for coordination with existing systems.

TOPPAN will run demonstrations of the new liquid leakage sensor in a joint booth with Inabata & Co., Ltd. at EXPO COMM Wireless Japan, which will be held from May 29 to 31 at the Tokyo Big Sight international exhibition center (West Exhibition Halls 3 and 4).

Background

Demand for digital transformation (DX) and automation in factories is rapidly increasing, particularly in Japan, which is facing challenges associated with an aging population, declining birthrates, and labor shortages. The number of incidents of leakage from pipes and other equipment is increasing as a consequence of aging buildings at factories and industrial facilities, making it necessary to conduct regular inspections and checks with limited manpower over wide areas of facility premises and in locations that are difficult to access. This has therefore prompted demand for systems that facilitate remote and automated detection of liquid leakages.

To address these challenges, the TOPPAN Group’s new sensor makes a wider range of liquid leakage detection possible with a wireless communication function for connectivity in any location and a detection band in tape form that applies printed wiring technology to provide flexibility for installation. Linking up with e-Platch™ facilitates centralized management of not only liquid leakage but also various other parameters monitored in factories, such as temperature, humidity, energy, and abnormal sounds, to enable comprehensive enhancements in efficiency for the inspection work required at factories and facilities.

The TOPPAN Group is also planning to offer a new pricing plan that meets demand for lower initial costs for adoption of e-Platch™ and to provide an external API that enables data coordination with existing visualization systems already installed at client companies.

Features

・Two types of detection band

Printed wiring technology has been applied to create detection bands in tape form that provide flexibility for installation in a wide range of locations. The two types of detection band—one for water and chemicals, another for oil—also allow for detection of a broad scope of liquids.

・Wireless connectivity in any location

Stable communication is possible even in locations that generally experience poor reception for radio waves, such as inside distribution boards and on equipment with limited access in effluent treatment areas and the like, where it is difficult to install a fixed line network. This facilitates remote monitoring at every point, including basement floors and clean rooms.

Future

The TOPPAN Group intends to further enhance functionality for liquid leakage sensors and e-Platch™ as a whole, and to drive sales expansion targeting 600 cases of adoption of the system by the end of fiscal 2025.

About the e-Platch™ smart inspection support service

e-Platch™ is a system that uses a wireless network to enable automated collection and visualization of various data required for equipment inspections. Using applications makes it possible to reduce the workload for inspection work because automated email alerts are sent when values exceed thresholds set for each sensor. As a retrofittable add-on DX solution, e-platch™ supports operational process improvement for inspection work.

TOPPAN uses e-Platch™ at its Kumamoto Plant, where efforts to cut loss resulted in a reduction of approximately 380 hours per month in inspection work in fiscal 2023, a decrease equivalent to roughly 70% of the time previously required. The plant has confirmed 50.4-million-yen in annual cost savings enabled by operational optimization, such as allocating freed up internal resources to handle work that was previously outsourced, and by loss improvement activities that leverage the data obtained. TOPPAN aims to harness e-Platch™ to contribute to more eco-friendly factory operation, which is a management objective for many companies, and is also focusing efforts on proposals that identify the challenges faced by each customer and estimate the potential benefits of introducing the service.

More information about e-Platch™:

https://solution.toppan.co.jp/smartdevices/service/eplatch.html (in Japanese)

About the TOPPAN Group

Established in Tokyo in 1900, the TOPPAN Group is a leading and diversified global provider committed to delivering sustainable, integrated solutions in fields including printing, communications, security, packaging, décor materials, electronics, and digital transformation. The TOPPAN Group’s global team of more than 50,000 employees offers optimal solutions enabled by industry-leading expertise and technologies to address the diverse challenges of every business sector and society and contribute to the achievement of shared sustainability goals.

https://www.holdings.toppan.com/en/

https://www.linkedin.com/company/toppan/